Meet the

startups.

Startups

OUR PORTFOLIOFrom healthcare and agriculture to bioindustry and materials, these are the startups growing the Life-Based Age.

90+

Startups

The ecosystem growing the Life-Based Age

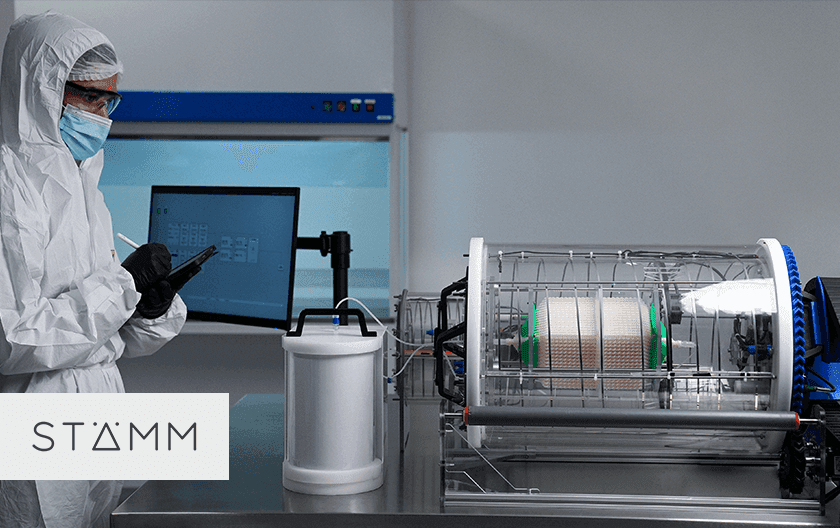

The future of biologicals, powered by living fossils

CRISPR-powered diagnostics for rapid, decentralized healthcare

A new paradigm in crop pollination

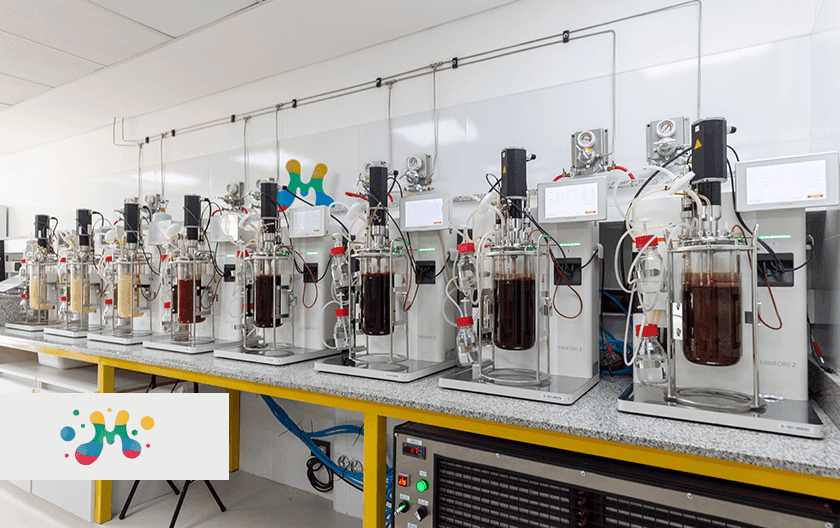

Replacing petrochemical food dyes with fungal ones

Redefining drug discovery by starting with patients

Green solvents engineered from natural compounds

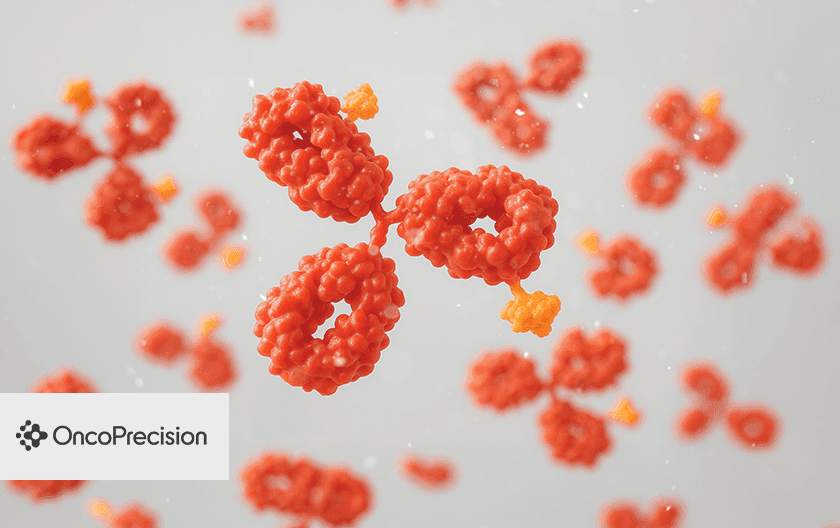

Transforming health with Single-domain Antibodies

Our full portfolio

Algalife

Platform for optimizing productive processes based on microalgae

APEXzymes

Low cost enzymes for greener and cost-effective industries

BioClé

Bacterial vesicles to transform digestive health through precise and effective delivery.

Visit Website

Elytron Biotech

AI-powered biotech platform accelerating sustainable microbial solutions

Visit Website

Geoprot

Non-AI revolutionary method for protein function analysis and prediction

Levya

Fats and oils produced with yeast to replace ingredients with a high environmental impact.

Visit Website

Lipock

Nanocápsulas lipídicas que mejoran la eficacia de activos volátiles e hidrofóbicos.

Visit Website

New Organs Biotech

Combining gene-editing with precision medicine to solve organ shortage

Visit Website

Nunatak Biotech

Transforming extreme microbes into solutions for sustainable agriculture

Visit Website

PreGen

Affordable and accessible cancer prognosis tests.

Scitherm Therapeutics

Novel small molecules for targeted fat loss without appetite suppression

Visit Website

Synthetic Ocular Restoration

Revolutionizing the treatment of corneal diseases and visual impairments

Visit Website

Werken Vac

Self-amplifying RNA vaccine for fish

Global co-investors in our portfolio companiess

Explore

© Grid Exponential

All rights reserved.

Teodoro García 2474, Buenos Aires, Argentina